-

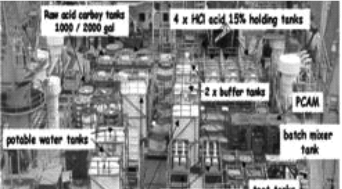

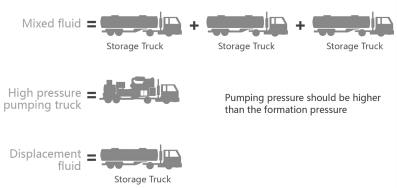

Equipment Requirements

The above equipment is only for reference, the actual equipment according to the field conditions.

01 -

Prepare treatment fluid

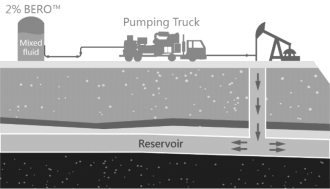

Treatment fluid:V = (2-5% BERO) + (95-98% Formation Water) Water Temperature:50-70℃ Displacement fluid:Formation water or sewage water

The temperature of the treatment fluid requires between 50-70℃, because the temperature of the reservoir usually between 50-70℃, in order to let BERO spread faster and better, we require to heat up the treatment fluid.02 -

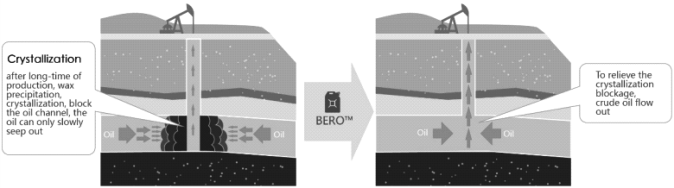

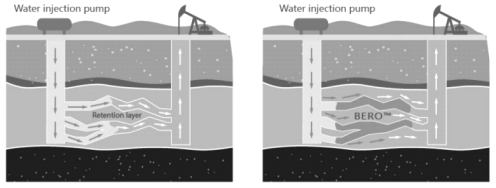

BERO treatment process

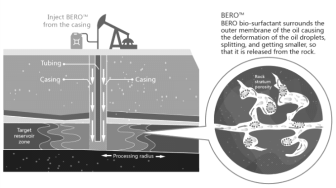

BERO its easy to understand by operation, concentrate liquid BERO will transported to the field by storage drums, dilute 2-5% of BERO with 95-98% of formation water, and use high-pressure pumping equipment to squeeze treatment-fluid into target payzone.

03

-

The product shelf life its 3 years, no special requirements for transportation and storage. But due to below 0 degree Celsius will affect the effectivity of the product.

One time stimulation process, and the effectively period last more than 12 months.Total production minimum increases 20% above

01 -